Anti Acid Tiles, Bricks & Mortars

Free of aldehyde, 2-component synthetic resin mortar based on furan resin for jointing and bedding bricks, tiles and shapes. For the

production of chemically, thermally and mechanically resistant coverings and linings.

Typical applications are tile and brick linings in the chemical industry, for waste and process water treatment, in pits or secondary containments, in sewers, for traffic and reloading areas, for neutralization plants and acid pickling lines.

It is electrically conductive and is particularly suitable for battery rooms or rooms exposed to solvents.

For the electrically conductivity of the system, the information in the chapter "Testing the electrostatic conductivity" must be observed.

Aldehyde-containing, 2-component synthetic resin mortar based on furan resin for bedding and jointing board layers, bricks and shapes.

For the production of chemically, thermally and mechanically resistant coverings and linings.

Typical applications are tile and brick linings in the chemical industry, for waste and process water treatment, in pits or secondary containments, in sewers, for traffic and reloading areas, for neutralization plants and acid pickling lines.

Aldehyde-free 2-component synthetic resin mortar based on furan resin, resistant to hydrofluoric acid; for bedding and jointing tile linings, bricks and shapes. For the production of chemically, thermally and mechanically resistant coverings and linings.

Typical applications are tile and brick linings in the chemical industry, for waste and process water treatment, in pits or secondary containments, in sewers, for traffic and reloading areas, for neutralization plants, acid pickling lines and phosphoric acid plants.

It is electrically conductive and is particularly suitable for battery rooms or rooms exposed to solvents.

For the electrically conductivity of the system, the information in the chapter "Testing the electrostatic conductivity" must be observed.

Aldehyde-containing, 2-component synthetic resin mortar based on furan resin; for bedding and jointing board layers, bricks and

shapes. For the production of chemically, thermally and mechanically resistant coverings and linings.

Typical applications are tile and brick linings in the chemical industry, for waste and process water treatment, in pits or secondary containments, in sewers, for traffic and reloading areas, for neutralization plants and acid pickling lines.

It is electrically conductive and is particularly suitable for battery rooms or rooms exposed to solvents.

For the electrically conductivity of the system, the information in the chapter "Testing the electrostatic conductivity" must be observed.

Halogen-free 2-component water glass mortar for the construction of filled joint- and hollow joint- applied acid resistant tile and brick

linings on floor areas.

Laying of acid resistant tiles and bricks for floors, trenches and foundations; acid resistant tile and brick linings for towers and pipes

Halogen-free 3-component water glass mortar for the construction of filled joint- and hollow joint- applied acid resistant tile and brick

linings on floor areas.

In contrast to traditional silicate mortars, the mortar cannot only be applied in acidic areas but also in neutral areas, i.e. outdoors.

Linings at exposure to sulphuric acid and water at moderate temperature; brick lining with initial tension; laying and jointing of ceramic or carbon based tiles, bricks and formed components

Linings in zones of temperature changes and frequent transitions between dry and humid exposure e. g. in venturis an quenches and in industrial flue gas cooling; laying and jointing of ceramic or carbon based tiles, bricks and formed components

Alkadur K 36 is an epoxy resin based three-component system offering extensive chemical resistance to dilute acids, alkalis, salts, salt solutions, oils, greases.

Alkadur K 36, when used as jointing cement, is filled into the joints using a trowel or a jointing injector.

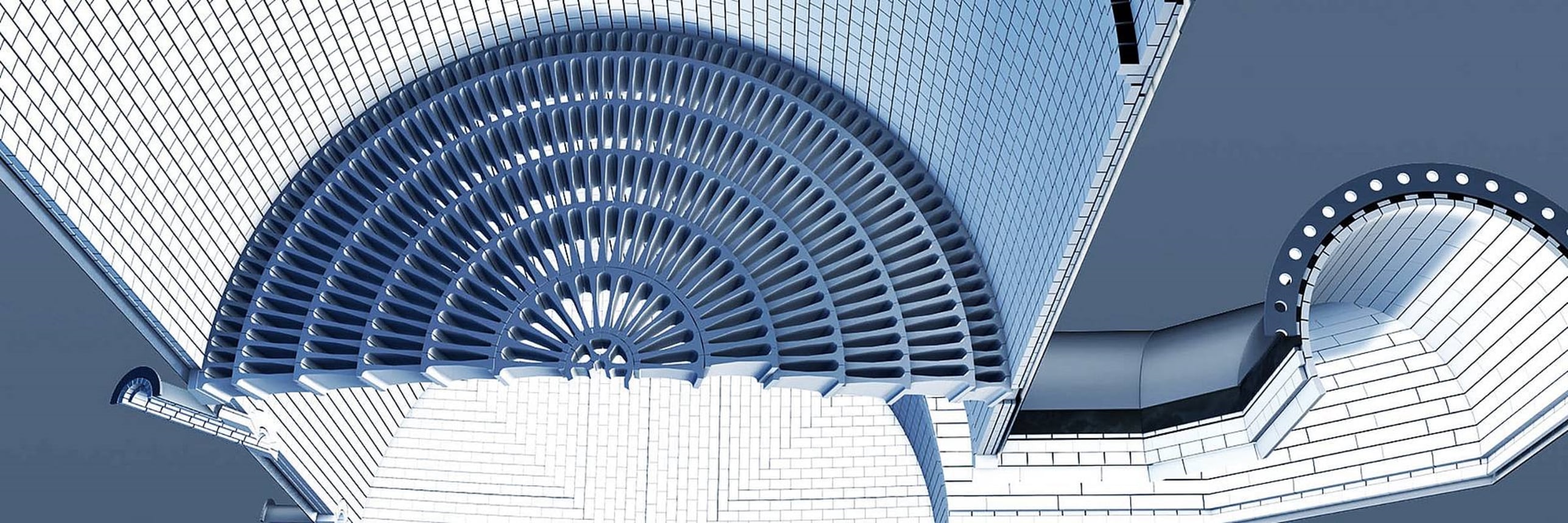

Alkadur K 36 is used for bedding and jointing ceramic brick and tile toppings as well as stoneware tiles for floor toppings and for basin and tank linings, particularly in breweries, production facilities for soft drinks, dairies, butter and cheese producers as well as many other manufacturing sectors. Alkadur K 36 is also suitable for tiling swimming pools, including pools containing sea water or thermal spa water. Service temperature range: to 60 °C.

Alkadur K 75 is an epoxy resin based three-component system offering extensive chemical resistance to dilute acids, alkalis, salts, salt solutions, oils, greases.

Alkadur K 75, when used as jointing cement, is filled into the joints using a trowel or a jointing injector.

Alkadur K 75 is used for bedding and jointing ceramic brick and tile toppings as well as stoneware tiles for floor toppings and for basin and tank linings, particularly in breweries, production facilities for soft drinks, dairies, butter and cheese producers as well as many other manufacturing sectors.

Alkadur K 75 is also suitable for tiling swimming pools, including pools containing sea water or thermal spa water.

Service temperature range: to 60 °C.

● low water absorption (apparent porosity) in order to minimize penetration of aggressive media

● high SiO2

content for being as siliceous as possible (resistance against acids)

● low contents of Al2O3

●Fe2O3

● CaO and MgO, because exactly these components show high acid solubility

● when being used as floor lining or in vessels with

abrasive components in the aggressive media

● good thermal shock resistance

● extremely low dimensional tolerances

Carbon and Graphite products with high temperature and chemical resistant (specially against alkaline solutions and HF) and good mechanical strength are available in different shapes like standard bricks, tubes, support beam and customized shapes.

Seamless, elastic coating for the protection of concrete substrates that are subject to mechanical stress. The cured system has a

plain-coloured, smooth surface and is suitable for fork lift traffic.

Seamless, elastic coating for the protection of concrete and steel substrates. The cured system has a uni-coloured, smooth surface.

Coating of concrete or steel substrates with or without subsequent tile or brick linings.

Laminate system for producing chemically resistant and fluid-resistant panels on concrete and steel surfaces. To improve the resistance, it can be covered with tiles or bricks and is suitable for application on concrete and steel surfaces.

It is also possible to applied the system as a self-supporting constructional laminate. The possible application depends on the project-specific demands.

To produce chemically resistant, fluid-resistant and thermally stable layers. For panelling tanks, columns, reactors, towers or channels or as the surface for tiles or bricks, also for foundations or concrete surfaces; as a part of construction laminates.

Laminate system for producing chemically resistant and fluid-resistant linings on concrete and steel surfaces. The system can be

covered with tiles or bricks to increase durability. It is also possible to applied the laminate as a self-supporting constructional laminate.

The possible application depends on the project-specific demands.

To produce chemically resistant, fluid-resistant and thermally stable layers. For tanks, columns, reactors, towers or channels or as the

surface for tiles or bricks, also for foundations or concrete surfaces; as a part of construction laminates.

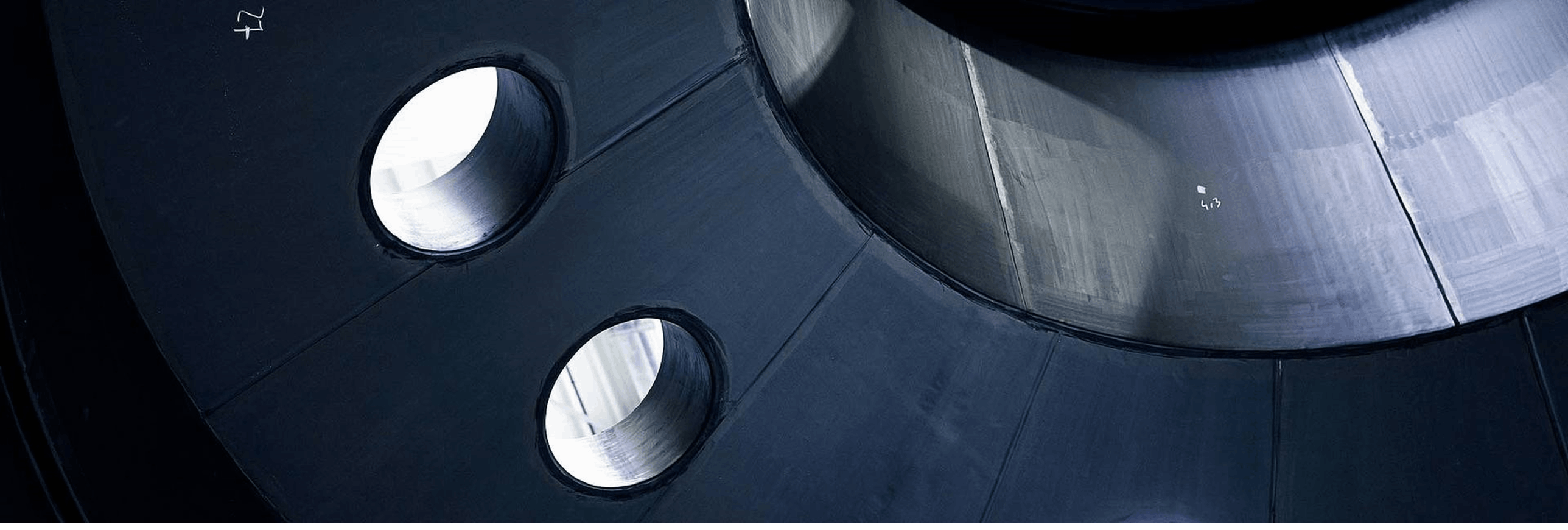

Pre-vulcanized, two-ply soft rubber lining based on chlorobutyl rubber (CIIR).

Depending on the requirements, the layer thickness of the rubber sheet can be 2–6 mm.

Rubber lining is mainly used in the following

applications

● Storage container

● And a multitude of other applications

Pre-vulcanised, two-layer soft rubber coating based on chlorobutyl rubber (CIIR) and PVC.

Depending on the requirements, the layer thickness of the rubber sheet can be 2–5 mm.

Rubber lining is mainly used in the following applications:

● HCl pickling plant

● HCl storage tanks

Tempered resp. pre-vulcanized, single-ply soft rubber lining based on chlorobutyl rubber (CIIR) and chloroprene rubber (CR).

Depending on the requirements, the layer thickness of the rubber sheet can be 2–6 mm.

For the design according to the national technical approval, please refer to the TI/VA: KERABUTYL BS DIBt 101K.

Rubber lining is mainly used in the following applications:

● Sealing layer for sealing surfaces and secondary containments

● Sealing membrane

● Storage tanks

Self-vulcanizing, single-ply soft rubber lining based on bromobutyl rubber (BIIR).

Depending on the requirements, the layer thickness of the rubber sheet can be 2-6 mm.

Rubber lining is mainly used in the following applications:

● Systems with vacuum stress

● Systems with high operating temperatures

● HCl storage and process tanks

● Phosphoric acid plants

● Flue gas cleaning plants

Pre-vulcanized, two-ply soft rubber lining based on bromobutyl rubber (BIIR).

Depending on the requirements, the layer thickness of the rubber sheet can be 3-6 mm.

Rubber lining is mainly used in the following applications:

● Systems with high operating temperatures

● HCl storage and process tanks

● Phosphoric acid plants

● Flue gas cleaning plants

Hard rubber lining based on natural rubber (NR) that is vulcanised in the autoclave. Depending on the requirements, the layer thickness of the rubber sheet can be 3 - 6 mm.

VULCOFERRAN 2190 is recommended as a protective lining for structural components made of steel that are subjected to chemical

exposure.

Its primary spectrum of application is the lining of reaction and process tanks that are operated at high temperature ranges.

Graphite-filled, single-layer hard rubber coating based on natural rubber (NR) and styrene-butadiene rubber (SBR), which can also be

applied on site and vulcanized with hot water or steam.

Depending on the requirements, the layer thickness of the rubber sheet can be 3–6 mm.

Rubber lining is mainly used in the following applications:

● Vessels in chlorine chemistry (membrane process)

● HCl tanks in pickling and regeneration plants

● Storage container

● Waste incineration plants

Pipes and fittings, reinforced with glass fibre with and added thermoplastic inner liner (choice of PTFE, PVDF, PE, PP, PVC, etc) KERAPOLIN® – Pipes and fittings of glass fibre are dual-laminate of glass fibre reinforced unsaturated polyester or vinyl ester resins.

A phenolic resin-based thermoset material which provides. customized shaping options for process equipment and piping.

durable branded material that consists of a chemical protection layer according to DIN or customer requirements and a supporting laminate made from glass-fibre-reinforced unsaturated polyester or vinyl ester resins. Suitable thermosetting resins are selected according to requirements and the operating environment. The laminate achieves adhesive shear strengths of up to 42 N/mm.

Alphacor type E pipes feature excellent chemical resistance combined with high rigidity. These properties result, firstly, from the almost consistently high resin content across the entire pipe wall thickness and secondly, from reinforcing material, which consists mainly of glass fiber mats. This type of pipe has performed especially well in chlor-alkali electrolysis.

BEKAPLAST is the ideal combination of stability, safety and resistance.

The special aspects of the BEKAPLAST system are the special, conically widening large anchor studs on the reverse of the plate. They create a permanent mechanical connection between the plastic lining and the concrete. In addition, they prevent differential expansion.

The size, shape and arrangement of the studs are the result of intensive development work aimed at achieving the best possible anchoring of the plates.

HTML Website Creator